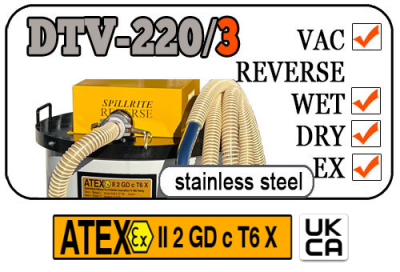

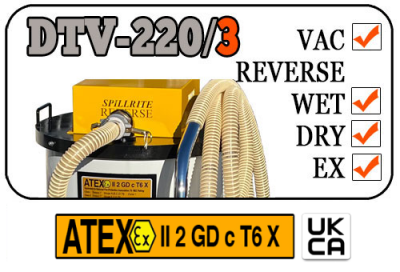

Drum Top Vacuum 220 Cyclone Combo HEPA ATEX UKCA

This Drum Top Vacuum cyclone combo is a pneumatic drum vacuum system with either triple or twin venturi's, bolted to a mild/stainless steel lid with stainless steel socket bolts and suits standard steel drums. The system produces high vacuum and is designed for light dry waste like dusts, powders, wood chips and most dry waste. The system is fitted with a dry filter/bag can be used for most dry waste. When fitted with reverse filter clean and a cyclone they are effective for the recovery of fine dusts.

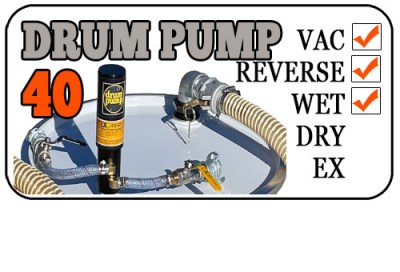

All Spillrite Drum Top vacuums can be configured as follows;

• Vacuum only wet

• Vacuum only wet and dry

• Vacuum only wet dry Explosion proof

• Vac and reverse - wet dry reverse filter clean

• Vac and reverse - wet dry reverse filter clean Explosion proof

• HEPA filtration unit

RDTV220/EX/CycloneHEPA

Drum Top Vac - 220 cfm 3 venturi - CYCLONE COMBO with HEPA Filter

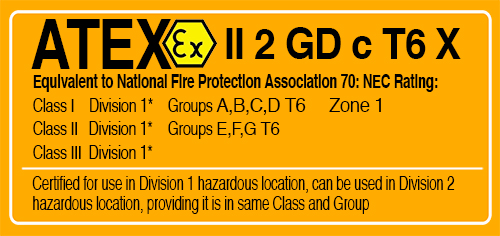

ATEX and UKCA certified pneumatic industrial explosion proof vacuum.

High powered industrial dry vacuum WITH CYCLONIC SEPARATOR & HEPA filtration.

Spillrite EX models have

- no ignition source

- no heating element

- will not cause sparking when in operation

Power head is constructed from powder coated alloy and when atop the steel drum and placed on the ground and connected to the supplied earth grounding strap any static charge will dissipate into the ground or through the anti-static suction hose.

The latest combustible dust vacuum from Spillrite Vacuums UK is the the Drum Top Vacuum 220 Cyclone Combo HEPA ATEX UKCA

With cyclonic separator and equipped with HEPA filtration is this model. Built on a stable and strong aluminium frame measuring 1220 mm long x 610mm wide and 1060mm high.

These units have been designed to be intrinsically safe in the following environments - Class I, Class II, & Class III environments, divisions 1&2.

Spillrite EX models have no ignition source, no heating element and will not cause sparking when in operation. Power head is constructed from powder coated mild steel and when atop the steel drum and placed on the ground or trolley and connected to the supplied earth grounding strap any static charge will dissipate into the ground or through the anti-static suction hose.

Platform trolley AS units have grounding chain from the metal trolley and the stainless steel drums are grounded to the trolley.

Platform trolley AS units have grounding chain from the metal trolley and the stainless steel drums are grounded to the trolley.

The platform trolley is made from a light metal frame which helps to allow Electro static dissipation (ESD) from the unit via a chain to the ground.

- Length 1220mm

- Width 660 mm

- Height 990mm

- Weight 45 kg

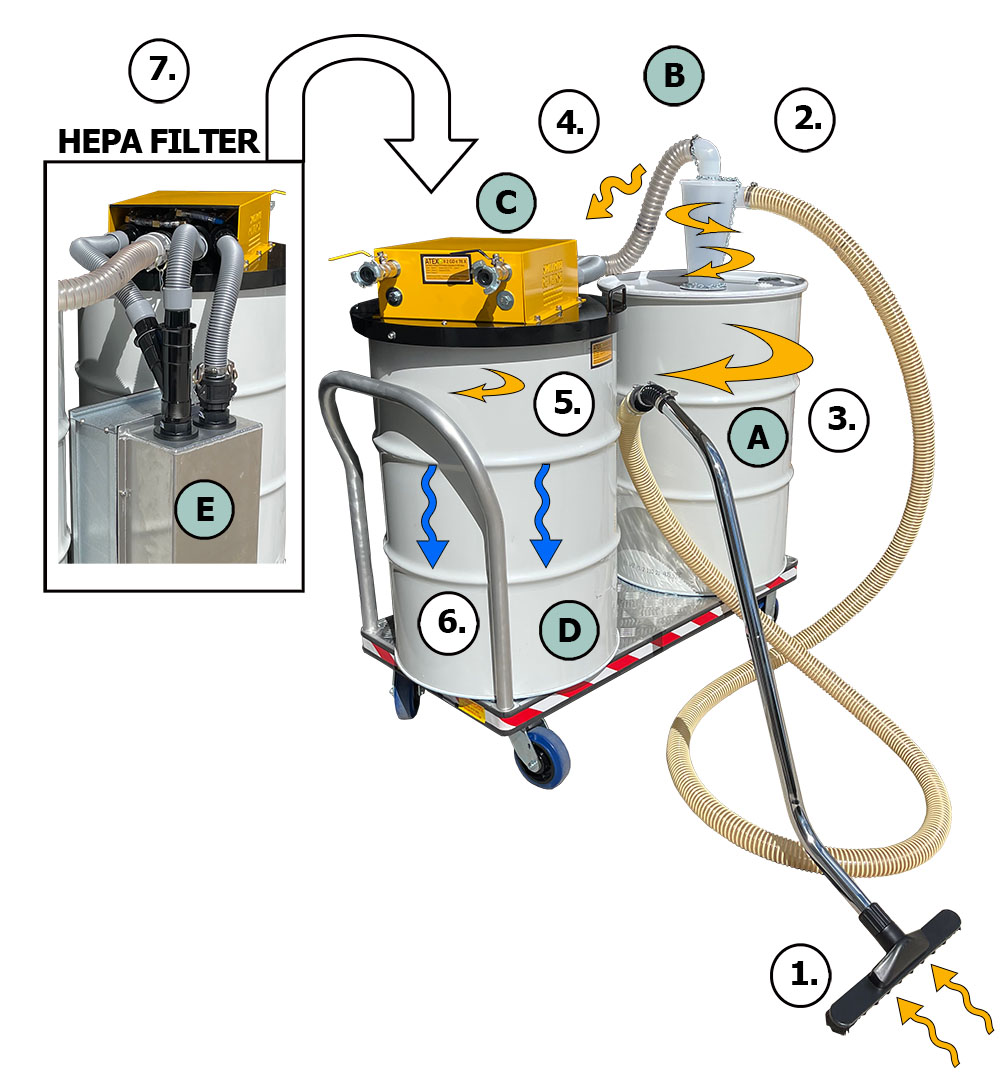

The pneumatic power head sits on top of 44 GALLON steel drum. The filtration is a two stage system that includes the cyclone mounted on a second 44 gallon steel drum. The RDTV220/EX uses an anti-static filter cartridge. When the RDTV is connected to the cyclone the separation is approximately 99% into the power drum and 1% into the Cyclone collection drum allowing far longer running times and less filter cartridge cleaning.

What is a cyclone and how does it work?

A cyclone is a device that helps to separate the dust particles from the main vacuum air stream and forces the particles down and into a collection drum and thereby preventing the majority of dust particles from travelimng through to the filter. The airflow when the cyclone is activated through vacuum creates a cyclonic vortex, much like a liquid whirlpool, sucking the waste downwards and the shape of the cyclone and the size of the aperture (hole) in the capture drum then prevents the majority of the particles from re-entering the vacuum flow and traveling back into the source of the vacuum, the power drum.

This process then allows the vacuum unit to operate for extended periods without the need to clean or replace the filter. The image below shows the approxiimate percentage of dust partiucles that stays in the capture drum and that travels through to the power drum and the filter. Not all cyclones work well. Spillrite uses cyclones that have been tested extensively in the field and we know they work.

|

|

Unit comes with a trolley to convert to a mobile dry vacuum unit.

- The RDTV220/EX has a powder coated anti-static metal silencer shroud bolted to an anti-static explosion proof alloy lid

- The chrome wand attached to the floor tool adds to the anti-static characteristics of the unit

- The unit comes with 3 metres of explosion proof smooth bore suction hose

- Metalic explosion proof anti-static fittings are used throughout the system

- A grounding chain is secured at the front of the trolley to allow a static dissipation path

- Metal couplings are used to atttach to the air fittings

- The lid is grounded to the steel drum via a wire across the steel lid/gasket

- The capture drum has a 44 gallon/200 litre capacity

THIS UNIT IS VACUUM ONLY WITH CYCLONE

Pneumatic Drum Vacuums are very SAFE.

- Pneumatic drum vacuums are powered by compressed air, they do not use electricity

- There are no moving parts to wear out, cause friction or create a spark

- Can be used in both wet and dry applications

- Designed and manufactured in Australia

- 4 times the power of electric vacuums

- Huge 5 metre water lift

- 5 year warranty

-

We build to order and ship within 3 business days

-

TURN YOUR OLD DRUM INTO A POWERFUL VACUUM SYSTEM. THE UNIT CAN BE CONFIGURED WITH REVERSE FILTER CLEANING.

| TECHNICAL SPECIFICATIONS - DRY - REVERSE FILTER CLEAN WITH CYCLONE |

|

| AIR SUPPLY MIN | 220 CFM |

| AIR SUPPLY FITTING | 3/4 " |

| VACUUM FLOW | 290 CFM |

| VACUUM RATING INCHES MERCURY | 17" MAX |

| VACUUM RATING MILLIBARS | 575 MB |

| FILL/PUMP OUT 44/55/205 DRUM | 75 SECONDS |

| VENTURI TYPES | TRIPLE RFC VENTURI'S |

| MAX SUCTION HOSE 1.5"/38MM | 80 FEET / 25 METRES |

COMBUSTIBLE DRY WASTE - Flour, Sugar, Metal dust, Coal dust, Most combustible dry waste

Included in kit:

RDTV220/EX EXPLOSION PROOF VACUUM INCLUSIONS;

EX Power head fitted to MILD steel lid

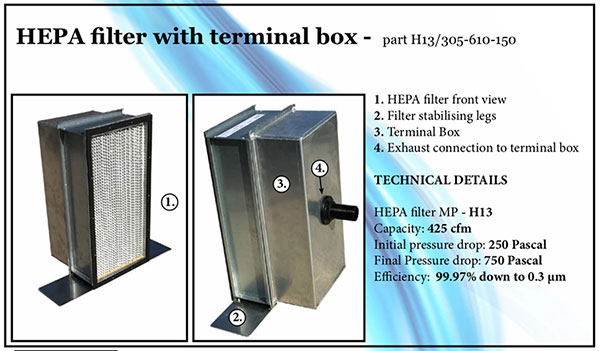

HEPA filter cartridge with terminal box

Gasket to seal unit to tank

EX plastic cyclone with upgraded anti static features to allow Electro static dissipation (ESD)

EX camlock fittings

EX suction hose x 3 metres

EX wand and floor tool

EX Filter cartridge

3/4" Chicago air coupling with ball valve

Trolley with grounding chain