Air operated oil drum pumps

|

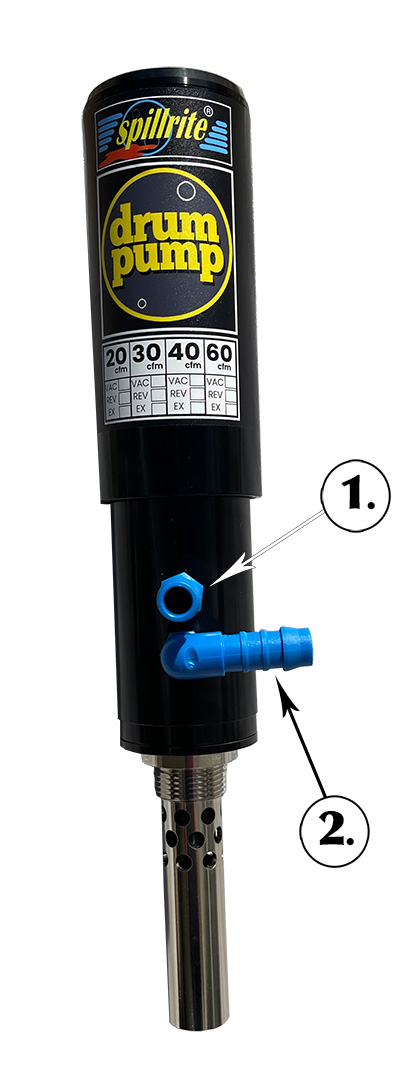

Air operated oil drum pumpsSpillrite drum pumps come in 4 power configurations. 20/30/40/60 and either vacuum (1) only or reversible (2). Lastly they come as standard or as anti-static ATEX certified. What is the difference? The 20 cfm model has low air consumption but high vacuum. It is pefect for all oils, fuels, coolant, grease, bilge and muds. It can suck the fluid from a sump or a drum. However it has low air flow so woukld not be good for spills on the ground. For spills you need higher air flow so the next model, the 30 cfm would be best. |

|

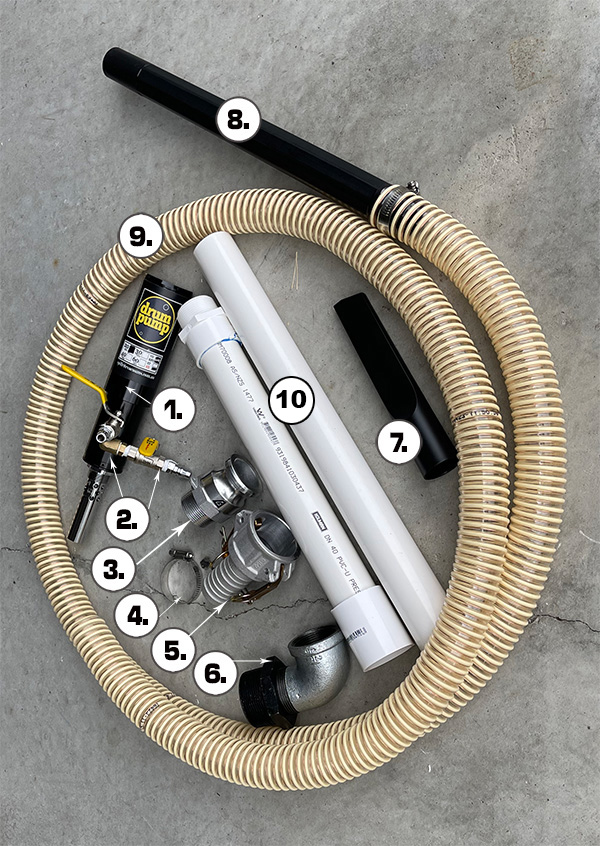

Reversible pump out kit accessories.Kit includes;

|

|

Nitto or 3/4" universal claw couplingThe 20 & 30 cfm drum pumps use a nitto fitting to connect to the factory air push in couplings. These pumps require less air to operate efficiently and effectively. For the high power 40 & 60 cfm drum pumps, universal claw couplings are needed to allow a higher air volume through the supply line which gives these pumps the extra power to vacuum up thicker and heavier fluids. |

|

20 cfm ATEX explosion proof drum pump with Nitto connection.The awesome power of the 20 cfm drum pump can fill the 200 litre drum in under 90 seconds. The pump has no moving parts and nothiong goes through the pump apart from air. The pump creates a vacuum inside the drum and when a suction hose is connected to the drum via the camlock set, the drum becomes a hugely powerful industrial vacuum system.

|