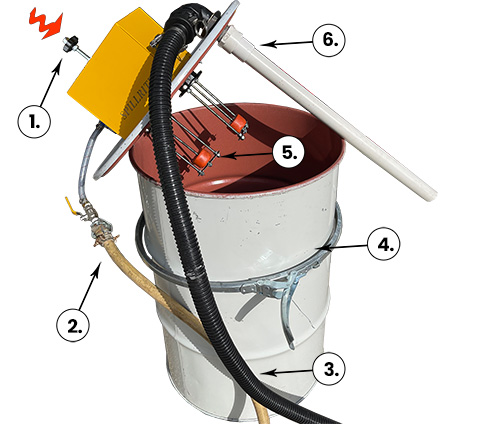

Reversible vacuum & pump out system.

The unit works as an industrial wet vacuum with the ability to reverse pump out the fluid into a second drum. The drum lid vacuum suits a 210 litre steel drum. 55 gallon drum lid vacuum.

|

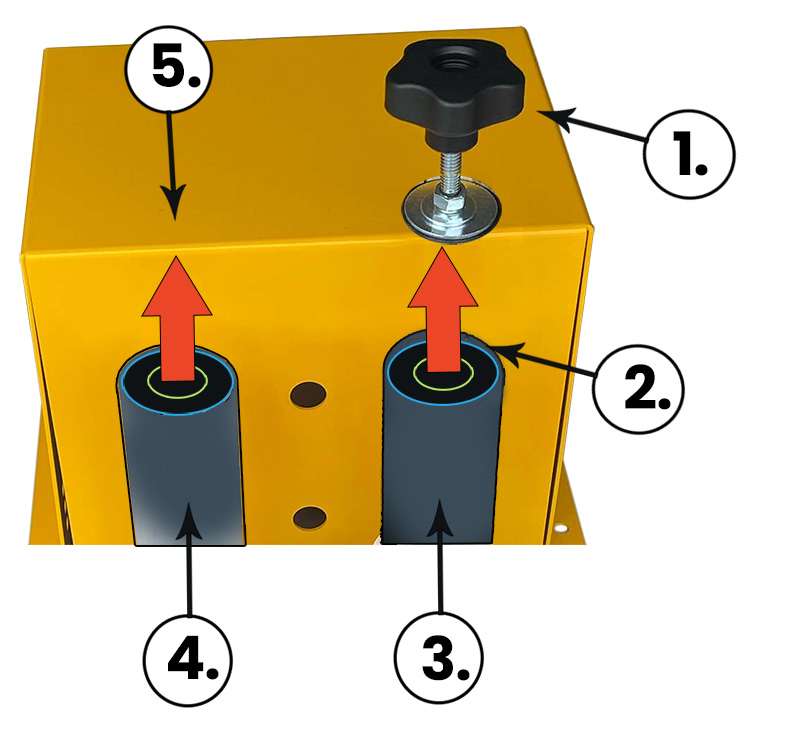

Reverse Drum Lid Vacuum process

- Reverse pump out screw handle

- Suction & reverse pump out port

- Drum lid lock ring

- Steel drum 44/55/205/210

- Drum dolly

- Vacuum control valve

- Reverse pump out valve

|

|

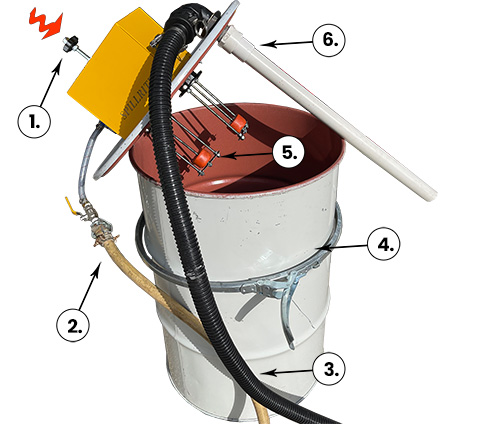

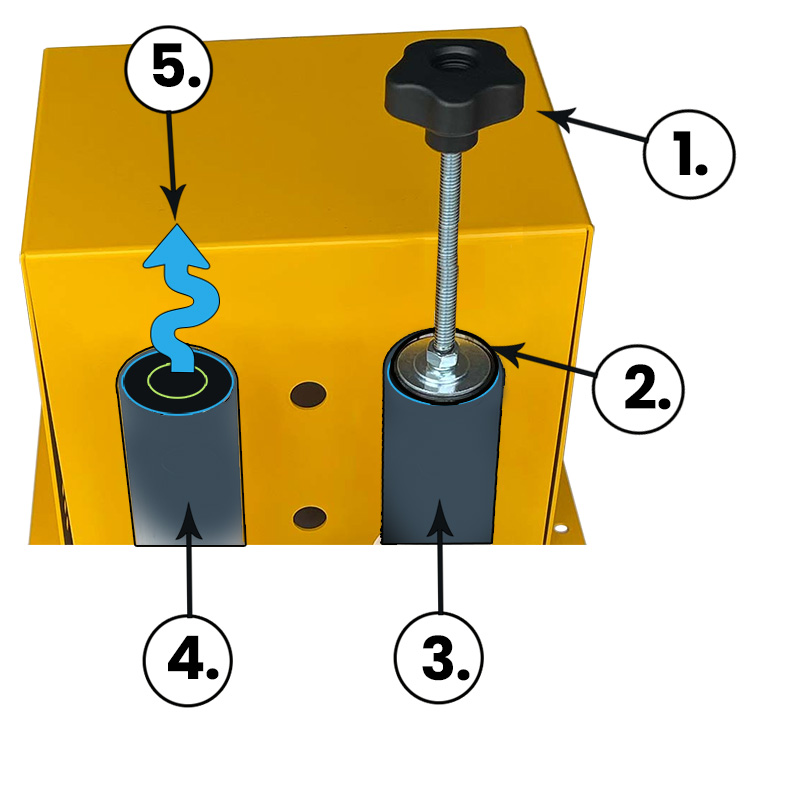

Reversible vacuum & pump out system.

- Reverse pump out screw handle

- Up position for vacuum

- Down position for reverse pump out

- Compressed air supply line

- Suction & pump out hose

- Drum lid lock ring

- Auto-shut off float valves

- Pump out internal drop pipe

|

|

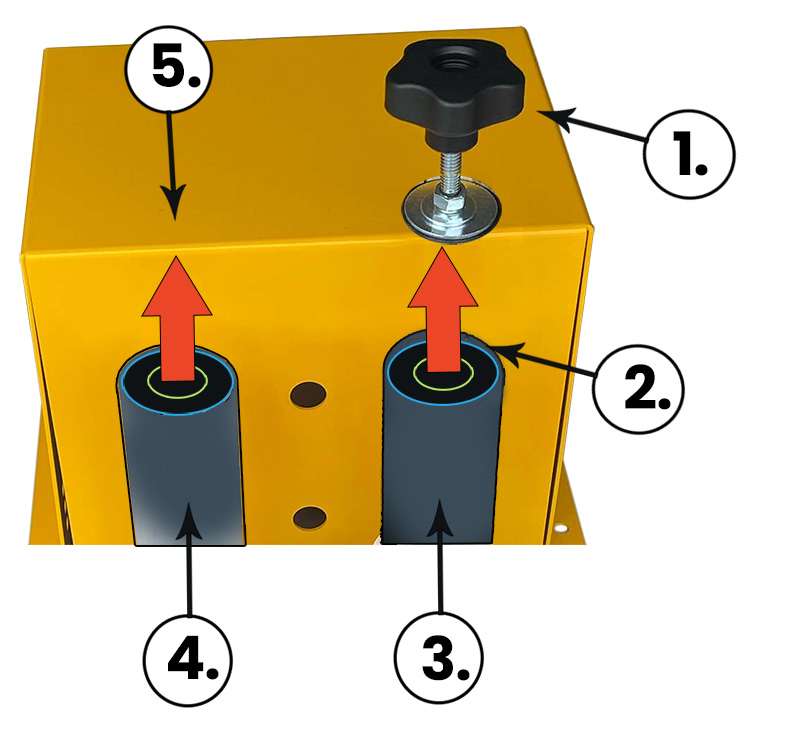

Operation of vacuum

- When screw handle (1) is up both internal venturi's (3 & 4) will be in operation for vacuum mode.

- Venturi exhaust expels into atmosphere when in vacuum operation(2 & 5).

|

|

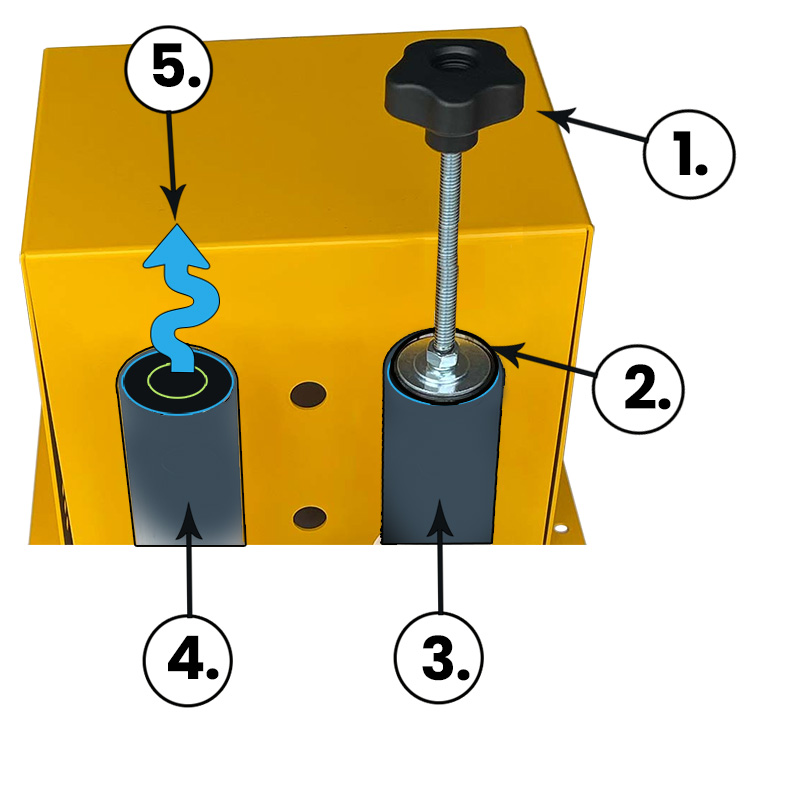

Operation of reverse pump out

- For reverse pump out mode the screw handle (1) needs to be in the down position (2) to block off one of the venturi exhausts. Tyhe bottom control valve needs to be acvtivated for the reverse mode jets to be activated.

- Venturi's 3 & 4 will be in reverse mode with the compressed air re-directed into the drum via the unique Spillrite reverse jets.

- Pressure will build up in the drum and then be released via the second venturi (4) and through the suction port preventing over pressurisation of drum.

- The Spillrite reverse method is completely safe and has been tested extensively over the last 15 years in every industrial scenario available.

|

|

The Spillrite twin reverse pump out system provides superior fluid pump out compared to single venturi systems. |